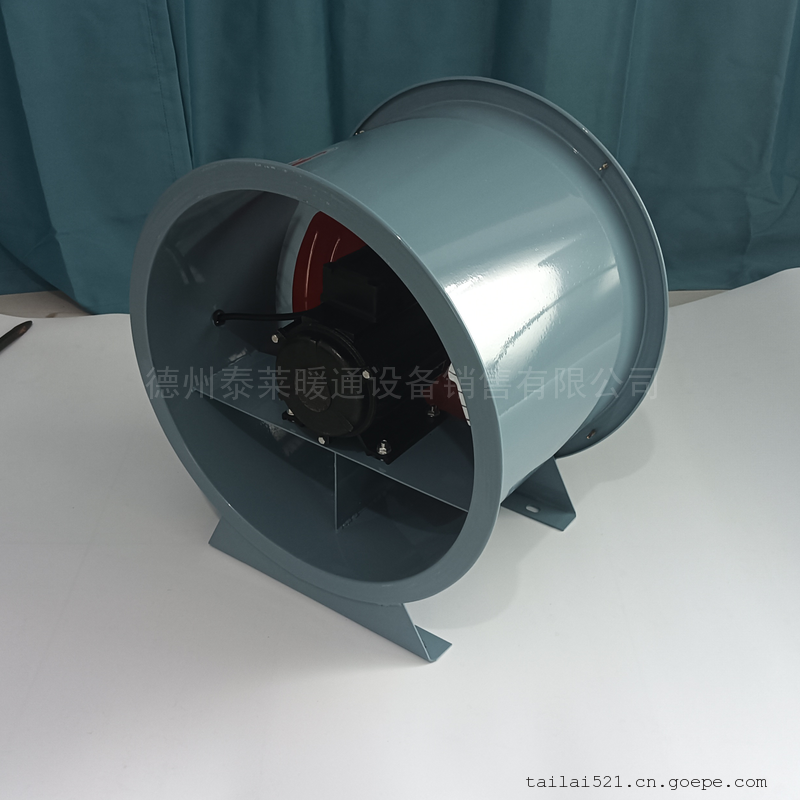

| | 品牌:泰莱 | | 型号:FBT35-11 | | 材质:玻璃钢 | |

| | 风机压力:低压风机 | | 性能:防腐风机 | | 用途:管道风机 | |

| | 轴功率:0.55 kw | | 叶片数:4 | | 重量:24 kg | |

| | 涡轮头性质:玻璃钢 | | 转速:1450 | | 配套电机功率:0.55 kw | |

| | 适用范围:400 | | | | | |

FBT35-11玻璃钢防腐防爆轴流风机依叶轮直径的大小分为NO2.8,NO3.15,NO3.55,NO4,NO4.5,NO5,NO5.6,NO6.3,NO7.1,NO8,NO9,NO10,NO11.2十三种机号,每一种机号的叶片数都为4片。叶片又可装成15°,20°,25°,30°,35°五种角度。因此,每一机号由于叶片安装角度的大小,主轴转速快慢的不同,风机的风压、风量及所消耗的功率也不相同。(具体性能详见性能表)

FBT35-11玻璃钢防腐防爆轴流风机性能表

| 机号 |

叶轮

直径mm |

叶轮

周速m/s |

主轴

转速rpm |

叶片角

度deg |

风量m3/h |

全压mmHg |

全压

效率 |

需用轴

功率kw |

采用轴

功率kw |

配用电机 |

| 型号 |

功率kw |

| 2.8 |

280 |

42.5 |

2900 |

15 |

1649 |

15.5 |

0.87 |

0.080 |

0.092 |

YSF-5622 |

0.120 |

| 20 |

2167 |

17.2 |

0.88 |

0.115 |

0.133 |

YSF-5632 |

0.180 |

| 25 |

2685 |

17.7 |

0.895 |

0.145 |

0.166 |

YSF-5632 |

0.180 |

| 30 |

2921 |

19.0 |

0.88 |

0.172 |

0.197 |

YSF-5632 |

0.180 |

| 35 |

3202 |

23.7 |

0.86 |

0.240 |

0.276 |

YSF-6322 |

0.250 |

| 21.3 |

1450 |

15 |

826 |

3.9 |

0.87 |

0.010 |

0.012 |

YSF-5014 |

0.025 |

| 20 |

1086 |

4.4 |

0.88 |

0.015 |

0.017 |

YSF-5014 |

0.025 |

| 25 |

1346 |

4.5 |

0.895 |

0.018 |

0.021 |

YSF-5014 |

0.025 |

| 30 |

1464 |

4.9 |

0.88 |

0.022 |

0.026 |

YSF-5024 |

0.040 |

| 35 |

1605 |

6.1 |

0.86 |

0.031 |

0.036 |

YSF-5024 |

0.040 |

| 3.15 |

315 |

47.8 |

2900 |

15 |

2339 |

19.6 |

0.87 |

0.144 |

0.166 |

YSF-6312 |

0.180 |

| 20 |

3074 |

21.8 |

0.88 |

0.270 |

0.238 |

YSF-6322 |

0.250 |

| 25 |

3810 |

22.4 |

0.895 |

0.259 |

0.298 |

YSF-6332 |

0.370 |

| 30 |

4141 |

24.2 |

0.88 |

0.309 |

0.355 |

YSF-6322 |

0.370 |

| 35 |

4545 |

30.0 |

0.86 |

0.430 |

0.495 |

YSF-7122 |

0.550 |

| 23.9 |

1450 |

15 |

1169 |

4.9 |

0.87 |

0.018 |

0.021 |

YSF-5014 |

0.025 |

| 20 |

1537 |

5.4 |

0.88 |

0.026 |

0.030 |

YSF-5024 |

0.040 |

| 25 |

1905 |

5.6 |

0.895 |

0.032 |

0.037 |

YSF-5024 |

0.040 |

| 30 |

2072 |

6.0 |

0.88 |

0.039 |

0.045 |

YSF-5614 |

0.060 |

| 35 |

2273 |

7.5 |

0.86 |

0.053 |

0.061 |

YSF-5624 |

0.090 |

| 3.55 |

355 |

53.9 |

2900 |

15 |

3367 |

24.6 |

0.87 |

0.261 |

0.300 |

YSF-7112 |

0.370 |

| 20 |

4426 |

27.7 |

0.88 |

0.379 |

0.436 |

YSF-7122 |

0.550 |

| 25 |

5484 |

28.4 |

0.895 |

0.473 |

0.544 |

YSF-7122 |

0.550 |

| 30 |

5965 |

30.6 |

0.88 |

0.564 |

0.649 |

YSF-7132 |

0.750 |

| 35 |

6542 |

38.0 |

0.86 |

0.787 |

0.905 |

YSF-8022 |

1.1 |

| 27.0 |

1450 |

15 |

1680 |

6.2 |

0.87 |

0.033 |

0.038 |

YSF-5024 |

0.040 |

| 20 |

2208 |

6.9 |

0.88 |

0.047 |

0.054 |

YSF-5614 |

0.060 |

| 25 |

2737 |

7.1 |

0.895 |

0.059 |

0.068 |

YSF-5624 |

0.090 |

| 30 |

2977 |

7.6 |

0.88 |

0.070 |

0.081 |

YSF-5624 |

0.090 |

| 35 |

3265 |

9.5 |

0.86 |

0.098 |

0.113 |

YSF-6314 |

0.120 |

| 4 |

400 |

60.7 |

2900 |

15 |

4806 |

31.6 |

0.87 |

0.475 |

0.546 |

YSF-7122 |

0.550 |

| 20 |

6316 |

35.2 |

0.88 |

0.688 |

0.791 |

YSF-8022 |

1.1 |

| 25 |

7826 |

36.1 |

0.895 |

0.859 |

0.988 |

YSF-8022 |

1.1 |

| 30 |

8513 |

38.8 |

0.88 |

1.021 |

1.175 |

YSF-8022 |

1.1 |

| 35 |

9336 |

48.3 |

0.86 |

1.427 |

1.641 |

YT90S-2 |

1.5 |

| 30.4 |

1450 |

15 |

2406 |

7.9 |

0.87 |

0.059 |

0.068 |

YSF-5624 |

0.090 |

| 20 |

3163 |

8.8 |

0.88 |

0.086 |

0.099 |

YSF-6314 |

0.120 |

| 25 |

3920 |

9.0 |

0.895 |

0.07 |

0.123 |

YSF-6314 |

0.120 |

| 30 |

4263 |

9.7 |

0.88 |

0.128 |

0.147 |

YSF-6324 |

0.80 |

| 35 |

4676 |

12.1 |

0.86 |

0.179 |

0.206 |

YSF-7114 |

0.250 |

| 4.5 |

450 |

34.2 |

1450 |

15 |

3427 |

10.0 |

0.87 |

0.107 |

0.123 |

YSF-6314 |

0.120 |

| 20 |

4504 |

11.2 |

0.88 |

0.156 |

0.179 |

YSF-6324 |

0.180 |

| 25 |

5581 |

11.5 |

0.895 |

0.195 |

0.224 |

YSF-7114 |

0.250 |

| 30 |

6070 |

12.3 |

0.88 |

0.231 |

0.266 |

YSF-7124 |

0.370 |

| 35 |

6658 |

15.3 |

0.86 |

0.322 |

0.370 |

YSF-7124 |

0.370 |

| 5 |

500 |

38.0 |

1450 |

15 |

4700 |

12.4 |

0.87 |

0.182 |

0.210 |

YSF-7114 |

0.250 |

| 20 |

6178 |

13.8 |

0.88 |

0.264 |

0.303 |

YSF-7124 |

0.370 |

| 25 |

7655 |

14.1 |

0.895 |

0.328 |

0.370 |

YSF-7124 |

0.370 |

| 30 |

8327 |

15.2 |

0.88 |

0.392 |

0.450 |

YSF-8014 |

0.550 |

| 35 |

9133 |

18.9 |

0.86 |

0.546 |

0.628 |

YSF-8024 |

0.750 |

| 25.1 |

960 |

15 |

3142 |

5.4 |

0.87 |

0.053 |

0.061 |

YSF-8026 |

0.370 |

| 20 |

4129 |

6.0 |

0.88 |

0.076 |

0.088 |

YSF-8026 |

0.370 |

| 25 |

5117 |

6.2 |

0.895 |

0.096 |

0.111 |

YSF-8026 |

0.370 |

| 30 |

5566 |

6.6 |

0.88 |

0.114 |

0.131 |

YSF-8026 |

0.370 |

| 35 |

6104 |

8.3 |

0.86 |

0.160 |

0.184 |

YSF-8026 |

0.370 |

| 5.6 |

560 |

42.5 |

1450 |

15 |

6596 |

15.4 |

0.87 |

0.318 |

0.365 |

YSF-7124 |

0.370 |

| 20 |

8667 |

17.2 |

0.88 |

0.461 |

0.530 |

YSF-8014 |

0.550 |

| 25 |

10739 |

17.7 |

0.895 |

0.578 |

0.665 |

YSF-8024 |

0.750 |

| 30 |

11689 |

19.0 |

0.88 |

0.687 |

0.790 |

YT90S-4 |

1.1 |

| 35 |

12812 |

23.7 |

0.86 |

0.961 |

1.1 |

YT90S-4 |

1.1 |

| 28.1 |

960 |

15 |

4360 |

6.8 |

0.87 |

0.093 |

0.106 |

YSF-8026 |

0.370 |

| 20 |

5730 |

7.5 |

0.88 |

0.133 |

0.153 |

YSF-8026 |

0.370 |

| 25 |

7101 |

7.7 |

0.895 |

0.166 |

0.191 |

YSF-8026 |

0.370 |

| 30 |

7724 |

8.3 |

0.88 |

0.198 |

0.228 |

YSF-8026 |

0.370 |

| 35 |

8471 |

10.3 |

0.86 |

0.276 |

0.318 |

YSF-8026 |

0.370 |

| 6.3 |

630 |

47.8 |

1405 |

15 |

9393 |

19.6 |

0.87 |

0.576 |

0.662 |

YSF-8024 |

0.75 |

| 20 |

12345 |

21.8 |

0.88 |

0.833 |

0.958 |

YT90S-4 |

1.1 |

| 25 |

15279 |

22.4 |

0.895 |

1.043 |

1.199 |

YT90L-4 |

1.5 |

| 30 |

16639 |

24.1 |

0.88 |

1.241 |

1.427 |

YT90L-4 |

1.5 |

| 35 |

18250 |

30.0 |

0.86 |

1.734 |

1.994 |

YT100L-4 |

2.2 |

| 31.7 |

960 |

15 |

6219 |

8.6 |

0.87 |

0.167 |

0.192 |

YSF-8026 |

0.370 |

| 20 |

8173 |

9.6 |

0.88 |

0.243 |

0.249 |

YSF-8026 |

0.370 |

| 25 |

10128 |

9.8 |

0.895 |

0.302 |

0.347 |

YSF-8026 |

0.370 |

| 30 |

11016 |

10.6 |

0.88 |

0.361 |

0.415 |

YT90S-6 |

0.750 |

| 35 |

12082 |

13.1 |

0.86 |

0.501 |

0.576 |

YT90S-6 |

0.750 |

| 7.1 |

710 |

59.3 |

1450 |

15 |

13444 |

24.9 |

0.87 |

1.048 |

1.205 |

YT90L-4 |

1.5 |

| 20 |

17670 |

27.7 |

0.88 |

1.515 |

1.742 |

YT100L1-4 |

2.2 |

| 21895 |

28.4 |

0.895 |

1.892 |

2.176 |

YT100L1-4 |

2.2 |

|

| 30 |

23815 |

30.6 |

0.86 |

2.255 |

2.593 |

YT100L24 |

3 |

| 35 |

26120 |

38.0 |

0.86 |

3.314 |

3.643 |

YT112M-4 |

4 |

| 33.7 |

960 |

15 |

8902 |

11.0 |

0.87 |

0.307 |

0.535 |

YT90S-6 |

0.750 |

| 20 |

11700 |

12.2 |

0.88 |

0.442 |

0.08 |

YT90S-6 |

0.750 |

| 25 |

14498 |

12.5 |

0.895 |

0.551 |

0.633 |

YT90S-6 |

0.750 |

| 30 |

15769 |

13.4 |

0.88 |

0.654 |

0.752 |

YT90S-6 |

0.750 |

| 35 |

17296 |

16.7 |

0.86 |

0.915 |

1.052 |

YT90S-6 |

1.1 |

| 8 |

800 |

60.7 |

1450 |

15 |

19235 |

31.6 |

0.87 |

1.903 |

2.188 |

YT100L-4 |

2.2 |

| 20 |

25280 |

35.2 |

0.88 |

2.754 |

3.167 |

YT100L-4 |

4 |

| 25 |

31325 |

36.1 |

0.895 |

3.441 |

3.579 |

YT112M-4 |

4 |

| 30 |

34078 |

33.8 |

0.88 |

4.091 |

4.705 |

YT112M-4 |

5.5 |

| 35 |

37370 |

48.3 |

0.86 |

5.716 |

6.573 |

YT132S-4 |

7.5 |

| 40.2 |

960 |

15 |

12733 |

13.9 |

0.87 |

0.554 |

0.637 |

YT90S-6 |

0.75 |

| 20 |

16735 |

15.4 |

0.88 |

0.798 |

0.918 |

YT90L-6 |

1.1 |

| 25 |

20737 |

15.8 |

0.895 |

0.999 |

1.149 |

YT100L-6 |

1.5 |

| 30 |

22556 |

17.0 |

0.88 |

1.187 |

1.365 |

YT100L-6 |

1.5 |

| 35 |

24739 |

21.2 |

0.86 |

1.661 |

1.910 |

YT112M-6 |

2.2 |

| 9 |

900 |

45.2 |

960 |

15 |

18132 |

17.5 |

0.87 |

0.99 |

1.139 |

YT100L-6 |

2.2 |

| 20 |

23830 |

19.5 |

0.88 |

1.428 |

1.645 |

YT112M-6 |

3 |

| 25 |

29529 |

20.0 |

0.895 |

1.797 |

2.067 |

YT132S-6 |

3 |

| 30 |

32119 |

21.5 |

0.88 |

2.137 |

2.458 |

YT132S-6 |

4 |

| 35 |

35227 |

26.3 |

0.86 |

2.990 |

3.439 |

YT132M1-6 |

2.2 |

| 10 |

1000 |

50.3 |

960 |

15 |

24874 |

21.7 |

0.87 |

1.690 |

1.944 |

YT112M-6 |

2.2 |

| 20 |

32691 |

24.1 |

0.88 |

2.483 |

2.804 |

YT132S-6 |

3 |

| 25 |

40508 |

24.7 |

0.895 |

3.004 |

3.501 |

YT132M1-6 |

4 |

| 30 |

44062 |

26.6 |

0.88 |

3.627 |

4.171 |

YT132M1-6 |

4 |

| 35 |

48326 |

33.1 |

0.86 |

5.060 |

5.825 |

YT160M-6 |

7.5 |

| 11.2 |

1120 |

586.3 |

960 |

15 |

31994 |

27.2 |

0.87 |

2.975 |

3.421 |

YT132M1-6 |

4 |

| 20 |

45927 |

30.3 |

0.88 |

4.307 |

4.953 |

YT132M2-6 |

5.5 |

| 25 |

5690 |

31.0 |

0.895 |

5.368 |

6.173 |

YT160M-6 |

7.5 |

| 30 |

961901 |

34.4 |

0.88 |

6.571 |

7.557 |

YT160M-6 |

7.5 |

| 35 |

67892 |

41.5 |

0.86 |

8.922 |

10.260 |

YT160L-6 |

11 |

机壳

采用泰山玻璃纤维有限公司生产的优质玻纤布,采用天津合成材料厂生产的名优不饱合树脂,该树脂属国际优质树脂,材质优良、色泽鲜艳;表面胶衣用中美合资天津爱科精细化工厂胶衣,内含抗紫外线剂,耐老化、强度高、重量轻、耐腐蚀;在冶金、化工等腐蚀性严重的厂房里它弥补了塑料风机老化、开裂、变形、寿命短等缺点,大大提高了其使用价值。本公司采用模具一次成型,一方面提高了外观的美观度,更好的增强了风机的整体强度,改变了传统工艺造成的外形笨拙,强度差的缺点,从而让产品更好的为客户的生产及使用做坚强的后盾。

机壳制作工艺如下:

机壳亦可采用冷轧钢板制作,表面防腐处理。

风机叶轮

FBT35-11玻璃钢防腐防爆轴流风机

采用模压玻璃钢叶轮,弯曲强度不小于196Mpa,各截面采用圆滑过度,外表光洁,无裂缝、缺口、毛刺等缺陷,整体效果好,风机做静平衡试验,按“刚性转子平衡精度”,等级取G6.3级,叶尖距风筒内壁间隙取30mm,误差不大于±10mm,风机气动合理、风量大、噪声低、效率高、耐腐蚀。

叶轮制作工艺如下:

适用范围

适用于办公大楼、商场、影剧院、医院、工厂企业车间、地下室等场所通风排气,所输送的应为不含粘性物质的气体,且气体温度不大于80℃,介质所含物质量不大于150mg/M3。

安装维护

1、机械安装不当,零部件错位,预负荷大

2、轴系对中不良

3、机器几何参数(如配合间隙、过盈量及相对位置)调整不当

4、管道应力大,机器在工作状态下改变了动态特性和安装精度

5、转子长期放置不当,改变了动平衡精度未按规程检修,破坏了机器原有的配合性质和精度

生产状况

扫一扫,手机浏览

扫一扫,手机浏览